Metal Corner, Drip Edge, & Termination Bar

Overview

NEW – Stainless Steel Corners & End Dams

Description

Mortar Net Solutions’ stainless steel inside & outside corners, and universal end dams help protect from moisture penetration at corners and end of runs in flashing installations. They are manufactured from 26-gauge Type 304 stainless steel for excellent durability and are soldered at joints to ensure leak-proof seams.

Install these flashing accessories under the flashing membrane being used. Their 26-gauge profile will allow for a smoother transition as opposed to field fabricated corners and end dams made from 40 or 60 mil flashing materials.

Type 304 stainless steel – ASTM A 240, ASTM A 666, ASTM A 480, ASTM A 167

Sizes and Packaging

| DESCRIPTION | GAUGE | WIDTH | LENGTH | HEIGHT | PIECES/BOX |

| End Dam | 26 | 4″ | 4″ | 4″ | 50 |

| Inside Corner | 26 | 6″ | 6″ | 4″ | 25 |

| Outside Corner | 26 | 10″ | 10″ | 4″ | 25 |

Metal Drip Edges

Description

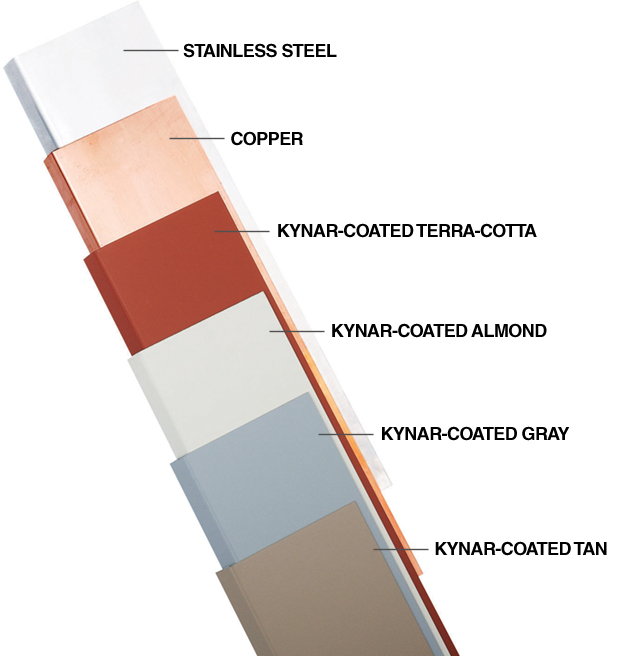

Mortar Net’s drip edge’s are available in stainless steel, cold-rolled copper, and four colors of Kynar-coated galvanized steel. All come with a 3/8” hemmed edge to create clean-looking edges during installation. Combine with our metal corner drip edges to complete the installation.

- Fast, easy, one-person installation

- Hemmed edge ensures water draining from the flashing will be directed away from the face of the building

- Stainless steel & cold-rolled copper are 100% recyclable

- Kynar colors include almond, gray, tan, and terra-cotta

Sizes and Packaging

| MATERIAL | GAUGE | WIDTH | LENGTH | PIECES/BOX | LF/BOX |

| Stainless Steel | 26 | 1-1/2″, 3″ | 8′ | 25 | 200 |

| Stainless Steel | 28 | 1-1/2″, 3″, 4″ | 8′ | 25 | 200 |

| Cold-rolled Copper | 24 | 3″ | 5′ | 20 | 100 |

| Kynar-coated Galvanized Steel | 24 | 3″ | 5′ | 20 | 100 |

Termination Bars

Mortar Net’s termination bars are available in PVC, stainless steel, and Aluminum. Mortar Net always recommends mechanically fastening termination bars at the top of flashing installations to help prevent moisture from getting trapped behind the flashing.

Features

- Pre-drilled holes 8″ o.c.

- T1 & T2 w/Lip options available

- Stainless Steel is Type 304

Benefits

- Fast, easy, one-person installation

- Reduces chances for leaks at top of flashing membrane

- Designed to last the life of the building

Sizes and Packaging

| MATERIAL | THICKNESS | WIDTH | LENGTH | PIECES/BOX | LF/BOX |

| PVC | 1/8″ | 1-1/4″ | 5′ | 20 | 100 |

| T1 Stainless Steel | 1/8″ | 1″ | 8′ | 25 | 200 |

| T1 Aluminum | 1/8″ | 1″ | 8′ | 25 | 200 |

| T2 Stainless Steel | 26-gauge | 1-1/2″ | 8′ | 25 | 200 |

| T2 Aluminum | 14-gauge | 1″ | 8′ | 25 | 200 |

Pre-formed Metal 90° Corner

For use in masonry cavity walls.

Features

- One piece

- Available in stainless steel, cold-rolled copper, Kynar®-coated galvanized steel in 4 colors (almond, tan, gray, terra-cotta) to match all TotalFlash drip edges

- Each leg: 3” W x 7 ½” long

- Stainless steel: 26 gauge

Benefits

- Fast, easy installation

- Reduces chances for leaks

- Creates a clean-looking corner every time

- Ideal for use with 14” High Corner Boots

- Ideal for use with the TotalFlash Cavity Wall Drainage Solution

Adjustable Metal Corner

Unique, patented metal corner for masonry cavity walls adjusts to fit nearly every angle wall.

Features

- One piece

- Available in stainless steel, cold-rolled copper, Kynar®-coated galvanized steel in 4 colors (almond, tan, gray, terra-cotta) to match all TotalFlash drip edges

- Each leg: 3” W x 7 ½” long

- Stainless steel: 28 gauge, 100% recyclable

Benefits

- Easily field adjustable from 325° to 22°

- Fast, easy installation

- Reduces chances for leaks

- Creates a clean-looking corner every time

- Ideal for use with 14” High Corner Boots

- Ideal for use with the TotalFlash Cavity Wall Drainage Solution

Custom Metal Drip Edges

Features

- One-piece

- Variable lengths up to 10’ to match building design requirements

- Available in stainless steel, cold-rolled copper, Kynar®-coated galvanized steel in 4 colors (almond, gray, tan, terra-cotta) to match all TotalFlash drip edges

- Stainless steel: 28 gauge, 100% recyclable

Benefits

- Shop-cut for a perfect fit around architectural details

- Significantly reduce installation time compared to field cutting individual drip edge sections

- Provide clean, continuous corners with no sharp edges

- Improve drip edge performance by eliminating drip edge breaks at corners

- Fit inside and outside corners and corners other than 900

- Arrive at the job site in easy-to-handle straight sections that are easily bent to conform to architectural details

- Ideal for use with the TotalFlash and CompleteFlash drainage systems

- Allow masons to spend less time installing flashing so they can quickly get back to laying brick